The West’s Reforestation Powerhouse: Inside Cal Forest’s Seed Processing Facility

Across the American West, reforestation starts long before a seedling enters the ground. It begins with the seed itself—its genetics, its viability, and the precision required to turn cones collected from burned landscapes into the forests of tomorrow.

At Cal Forest Nurseries, Mast’s Northern California nursery and the largest conifer seedling producer in the West, that process is underway at full speed. Every fall the team processes bushels upon bushels of native conifer cones collected across California and the Pacific Northwest, preparing the seed that will become millions of climate-resilient seedlings.

These seeds are the backbone of large-scale post-fire restoration.

Why Seed Processing Matters

Wildfire impacts more than trees—it can erase the natural seed sources needed for forests to regenerate on their own. That’s why Cal Forest’s growing capacity is so important. The nursery can process over 20,000 bushels of cones in a season, which depending on the species, can generate over 200 million seeds, enough genetic potential to reforest 600,000+ acres of fire-impacted land—nearly four times the size of Chicago. This level of throughput is essential for meeting the growing demand created by hotter, larger wildfires across the West.

As General Manager Nik Larum puts it:

Seed collection is a vital first step to reforestation. Every bushel of cone we process brings us one step closer to recovery.

—Nik Larum, General Manager of Cal Forest

Cal Forest employee picking up a handful of conifer seeds.

Cal Forest employee picking up a handful of conifer seeds.

Step 1: Releasing seed from native cones

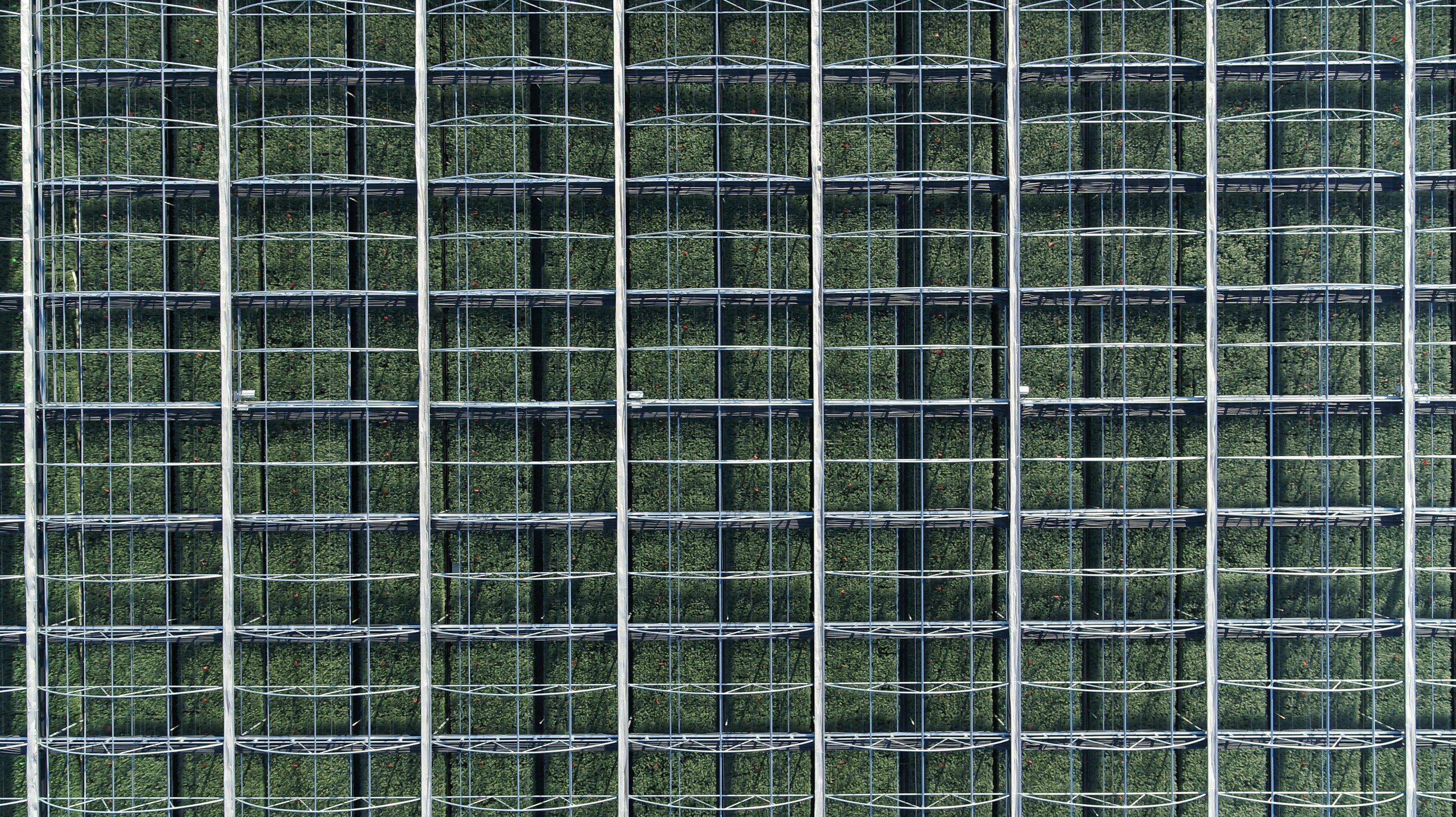

The process begins when wild, native cones arrive packed in bushel bags and are arranged on stacked racks inside high–air-flow greenhouses, where they are dried to open the cones and release the seeds.

When ready, the cones move into Cal Forest’s industrial tumbler, where rotation helps the seeds break free. The nursery’s cone tumbler can process 100+ bushels per day, releasing approximately 1.5 million seeds daily—enough to reforest thousands of football fields worth of land.

Catastrophic wildfires leave behind devastation: destroying seed in the canopy and seed banked in the soil. Our job is to collect and protect those genetics so forests can return.

-Nik Larum, General Manager of Cal Forest

Cal Forest employee places a bushel bag of cones onto the tumbler escalator.

Cal Forest employee places a bushel bag of cones onto the tumbler escalator.

Step 2: Cleaning and De-winging the Seed

The collected seed is still mixed with needles, twigs, and other cone debris. The next stop is the tiered screen Seed Cleaner, where seeds move across screens with carefully sized perforations. Everything larger than a seed is diverted off the top screen, everything smaller than a seed falls through, generating debris free seed that can then be purified for storage.

Once the seed is separated from the debris, many still retain their wings—thin appendages that must be removed before cold storage. For most species, Cal Forest uses a de-winger to gently separate the wings, creating cleaner seed that can be sown more efficiently.

Cal Forest employee operating the Clipper™ Seed Cleaner.

Cal Forest employee operating the Clipper™ Seed Cleaner.

Step 3: Separating Viable From Non-Viable Seed

Viability determines how many seedlings will ultimately grow. Using a gravity table, seeds are sorted by their weight:

- Dense, germ-filled seeds float to one side (the top left)

- Hollow, non-viable seeds move to the other

Cal Forest employee operating gravity table, sorting hollow seeds from viable seeds.

To verify accuracy, technicians X-ray batches of 50 seeds at a time. If a seed lot tests below specific standards for that species, it goes through the gravity table again, until it meets the standard. Each seed lot is then live germination tested to have a true viability data point.

X-ray scans allow Cal Forest technicians to determine if the seed is empty, or if an insect is in the seed.

X-ray scans allow Cal Forest technicians to determine if the seed is empty, or if an insect is in the seed.

Attention to detail is key. Data collected from the processing operation has critical impact on how seedlings are grown in the future.

—Nik Larum, General Manager of Cal Forest

Step 4: Ready for Sowing or Freezer Storage

Once seeds are cleaned, de-winged, sorted, and viability-tested, they’re packed and prepared for sowing later this winter at our nursery or are placed into our seed bank freezer where they can be stored for decades for future use..

Together, Cal Forest and their sister nursery Silvaseed support government agencies, landowners, tribal nations, and Mast’s own post-wildfire reforestation projects across 11 Western states.

Scaling Forest Recovery Across the West

The scale of Cal Forest’s work—paired with Mast’s reforestation operations and biomass-burial carbon removal projects—creates an end-to-end pathway for restoring forests after catastrophic fires.

From cone collection to seed cleaning to the moment young seedlings are planted in the ground, every step is rooted in precision and built for scale.

As hotter and more destructive wildfires reshape the West, the region will require millions more seedlings each year. Cal Forest is built for that challenge—and ready for what comes next.

If you or someone you know is interested in placing a seedling order with Cal Forest, click on the "Get in Touch" button below the photo.

Seedlings growing at Cal Forest Nurseries

Seedlings growing at Cal Forest Nurseries